ERP systems do and let you do, what they are designed for – i.e. run your day-to-day business operations and provide the current state of your business. Business managers and decision makers need to go beyond day-to-day functions, and look deeper than the current state of business. In process manufacturing, one such critical area where managers can find deeper insights is the sales backlog.

Sales Backlog Analysis

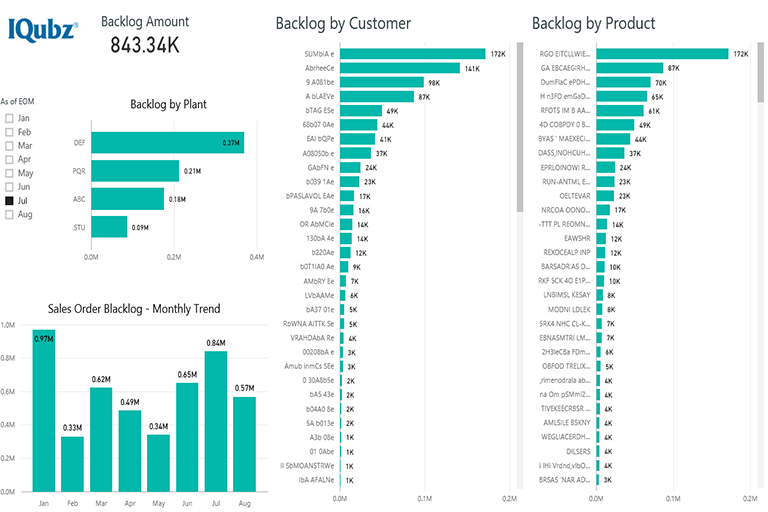

Sales backlog in manufacturing refers to customer orders not fulfilled on promised dates. Knowing the current state of your production backlog is critical, as it affects your customers, your production schedule, your plant capacity utilization and your revenue. A good manufacturing ERP system would provide you a standard report of the sales orders that have missed the scheduled delivery dates. It would also identify, which customers and products are being affected, for what quantities and importantly, the sales amount you thought you were going to invoice this month (or last month), but not going to any time soon.

This is all good for identifying what happened or what’s happening. To some extent, it will also help you identify why it happened on a case-by-case basis, for instance, it was the unavailability of material, higher level of defects, labor shortage, partial plant outage, or sheer mismanagement of resources, etc.

Reading between the Data

Managers become better decision makers when they understand, what’s going to happen, how to make something happen, and how to avoid something from happening. With all the data available, it is possible to get a deeper insight and let operations managers determine how they can utilize the plant optimally, avoid future production delays and reduce sales backlog.

In addition to the current backlog view, you can get snapshots of sales backlog gathered at specific intervals, such as every week. This will provide your operations managers how your sales backlog is trending period-over-period. Apart from understanding whether your sales backlogs are increasing or decreasing, it will also help uncover issues such as follows:

-

Which products or product types are consistently getting pushed to future dates?

-

Are the same customers being affected period-over-period?

-

Are the same work orders being pushed from one period to the next?

-

Are certain processes consistently taking longer than engineering estimates?

-

Is the backlog consistently caused by plant under-capacity?

Understanding these issues can help identify if there’s a commonality or pattern in the production delays. Whatever may be the underlying causes, this will help you remediate situations early on to avoid future delays by asking (and getting answers to) questions such as follows:

-

Which unreleased work orders are likely to be delayed in the future?

-

If delays are caused by the same resource unavailability every period, such as the requisite material, can it be sourced from another supplier with a quicker turn-around to avoid future delays? May a material substitute be used without affecting the quality of the product?

-

If the newly forecasted production delays are inevitable, will it result in leaving the plant idle? If so, which work orders can be moved to the front of the line to optimize the future plant capacity?

-

If the backlogs are caused by under-capacity of the plant, can the work orders be scheduled at a sister-plant that is being underutilized?

(Interact with sales backlog trend analysis dashboard in Power BI.)

Get the Picture with Data Snapshots

An ERP system doesn’t store the end-of-period snapshots of your sales backlog. It presents you what your current sales backlog is, right this minute as the data is constantly evolving to give you the current state of your business. With some time and effort you can gather data from your manufacturing ERP at regular intervals and tabulate it for your sales backlog trend analysis. However, data gathering and tabulating is time-consuming, and can be intricate. If your company has multiple plants managed in multiple ERP databases, this will add yet another level of complexity. Whether single plant or multiple plants, a well-designed manufacturing business intelligence solution can automate this data gathering and present this valuable trend analysis to your operations managers without the hours of repetitious effort.

Improved Plant Utilization

Sales backlog trend analysis can lead to effective production scheduling and accurate delivery forecasting. In addition to helping you provide realistic delivery dates to your customers, it can help optimize your plant utilization.

Ashu Shende is the Managing Partner at IQubz, a BI consulting firm based in Southern California. Contact Ashu via LinkedIn or by writing to ashu at iqubz dot com.

IQubz LLC

Foothill Ranch

Lake Forest (Orange County)

California, USA

+1 (949) 273-8876

IQubz LLC

Foothill Ranch

Lake Forest (Orange County)

California, USA

+1 (949) 273-8876